TEFLON®

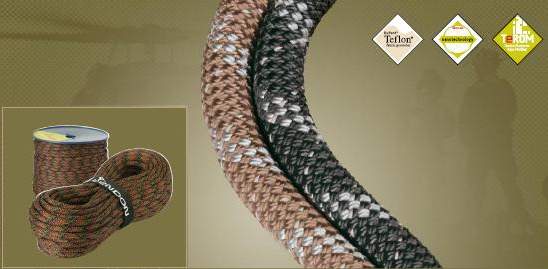

TENDON climbing ropes are the only ropes in the world to be produced with a DuPontTM TEFLON® fabric protector license. Ropes protected by a TEFLON® layer have extraordinary water and abrasion resistance. The TEFLON® layer also effectively prevents the intrusion of dust particles into the rope structure and thus increases its lifespan.

The rope is protected with a very stable organic resin based on organic fl uoridated polymers. The resulting protective fi lm reduces the surface energy of the textile material so much that it not only repels water, but fatty substances as well.

On the basis of physical principles, the special TEFLON® protection prevents absorption of water, fats and dust or abrasive particles on the rope’s surface. It also prevents the penetration of those particles into the internal structure of the rope, protecting the inside of the rope from damage. The TEFLON® layer gives our ropes superior properties for use, especially in damp or abrasive environments where ordinary ropes are vulnerable to serious damage.

In cooperation with DuPontTM , we have managed to increase the user value and safety of our ropes yet again after several months of research and practical testing.

By the addition of TEFLON® special additive, with which we impregnate our dynamic ropes, they demonstrate even better results with regards to the protection of sheath yarns from clinging dust! This results in the ropes being more resistant to abrasion, which otherwise shortens the lifespan of a rope and decreases the safety of a climber.

From now on, all dynamic ropes in the versions Protect Shield or Complete Shield will demonstrate an even greater safety and longer lifespan than previously available versions.